Professional solution

Engineer team

Power product engineer

You Baobin

Before 2014, You Baobin was involved in the research and development and testing of mechanical products such as generators, pumps and power, and was familiar with all the production details of mechanical products from 0 to 1.

Cleaning engineer

Liu Xiaojun

Liu Xiaojun personally established the innovative technical team of BISON cleaning machine, which guides the development of the core power of cleaning products, pumps and motors, and creates more opportunities for BISON cleaning machine products.

Power tool

He Chao

He Chao joined BISON in 2015 to lead the production supervision of power tools. He has long served the technical innovation and after-sales technical support of electric tools, and has a precise sensitivity to the quality details of electric tools.

Garden tools

Du Jinzhong

Du Jinzhong is the product engineer of BISON garden tools, he has been deeply involved in the garden tool industry for several years, and has professional views on raw material quality control, product assembly mode, quality inspection and mass production.

Detection process

Inspection of incoming IQC

All raw materials and products of BISON need to be sampled by a series of precision instruments, and only the products that pass the sampling can enter the raw materials warehouse. Guarantee product quality at the beginning.

Core parts description

Crankshaft

Forged steel is used to prevent breakage to a large extent and to improve the service life and smoothness of the product.

Crankcase

Adopt standard aluminum with high precision material to ensure fast heat dissipation and slow temperature rise to ensure the stability of machine work

Connecting rod assembly

Casting process, different from other factory’s die-casting process, high quality tensile strength, increase durability

Carburetor

The body is oxidized, the bottom cover has salt spray test, refer to the same accessories as Huayi, there are static hanging and oil measuring plane, greatly increase the atomization capacity and economic fuel saving

Camshaft

High-frequency quenching process, wear-resistant, long service life.

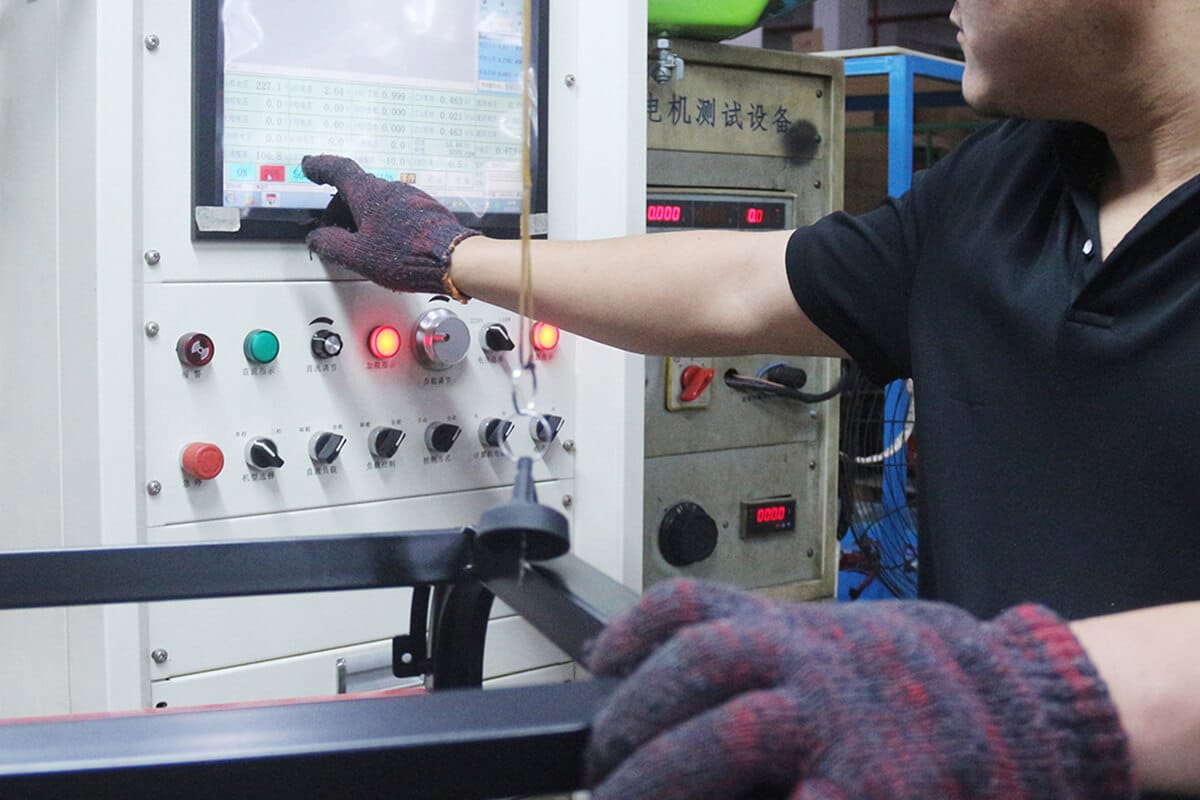

100% verify core performance

In order to ensure the stable output of core power, professional and old technology will be arranged for the core power of this order, and 100% full inspection will be carried out through digitization. Ensure the stable power of ex-factory products.

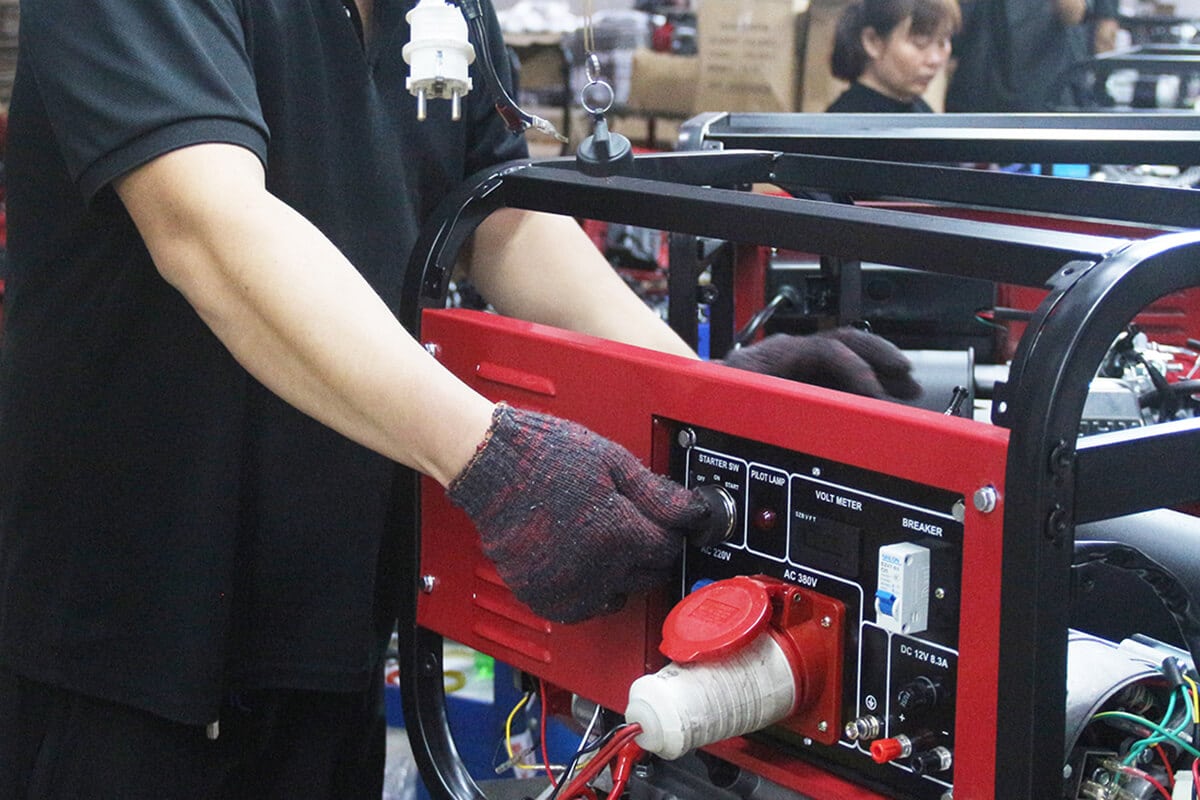

Product intensive sampling inspection

Before mass production, take 3% of the whole machine for assembly, and carry out 24-hour uninterrupted full-load work. After meeting the standard, it can be put into mass production. It is ensured that it can still be used for a short time in harsh environment, and the service life is prolonged.

Overall machine performance testing

After the assembly of the whole machine is completed, 100% of the on-line instruments are fully inspected.Make sure the machine works well before leaving the factory.

Artwork testing

Responsible for complete inspection of carton decals. Responsible for tracking customer’s brand and carton decal instructions.

Ensure the customer receives the perfect product

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)