two stage fire water pump

| no brand | 30 sets |

| OEM standard | 50 sets |

| OEM special | 100 sets |

WP30H Specifications

| Model | WP30H |

|---|---|

| Outlet Size(mm) | 80 |

| Inlet Size(mm) | 80 |

| Displacement Q. max(m3/h) | 75 |

| Lift H. max(m) | 25 |

| Suction (m) | 7 |

| Fuel Tank Capacity | 6.5L |

| Fuel option | #92, #95 Unleaded Gasoline |

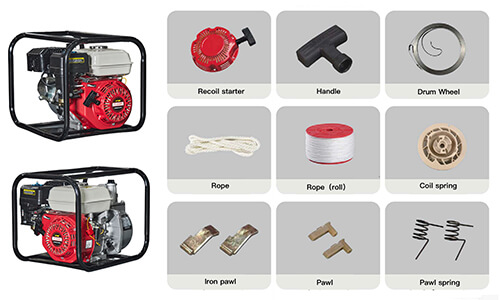

| Self start motor | Recoil start |

| Fuel consumption radio | ≤395g/kW/hh |

| Ignition system | T.C.I |

| Engine & Emission Specifications | |

|---|---|

| Engine Model | BS188F |

| Fuel Type | Gasoline |

| Engine Speed(RPM) | 3600 |

| Bore × Stroke(mm) | 88*64 |

| Engine Displacement(cc) | 390 |

| Engine/Motor Type | 1-Cylinder, Air-Cooled, 4-Stroke, Direct Injected,OHV |

| Engine Oil grade | #5W-40 |

| Fuel Capacity | / |

| Low Oil Shutdown/Alert | Yes |

| Recoil Start | Yes |

| Electric Start | Optional |

products description

BISON is a world-renowned water pump manufacturer. The two-stage fire water pump is designed to effectively handle emergency fire situations for commercial and residential fire protection. Ideal for water pump dealers looking to expand their inventory of high-quality fire water pump equipment.

Advantages of two-stage water pump:

Compared to single-stage pumps, advanced two-stage water pump systems use two impellers to gradually increase water pressure. It can provide high flow and more efficient fuel consumption, ensuring rapid response and fire extinguishing in major fire emergencies. The two-stage configuration spreads the workload, reducing stress on each impeller, and extending the life of your water pump

Fire water pump specially built for fire protection:

- Powerful engine: equipped with BS188F engine, the fire water pump can provide high-performance output and is suitable for long-term and demanding fire-fighting operations. The engine’s direct injection technology saves fuel and reduces emissions.

- Heavy-duty structure: we use sturdy materials and careful high-temperature-resistant design to ensure that the fire water pump can face high-temperature firefighting environments.

- Start mode selection: recoil start is conventional, electric start can be customized according to market demand, no need to manually absorb water, safer and more efficient.

- High suction and lift capacity: the suction depth can reach 7 meters and the lift height can reach 25 meters. It can easily manage the water supply from various water sources and has various application scenarios.

- Safety enhancements: An integrated low-oil shutdown feature automatically shuts down the engine to prevent damage, providing extra protection for the machine and firefighters.

Fire departments around the world are constantly looking for reliable, high-performance fire water pumps. BISON’s two-stage fire water pump meets fire protection standards and has great market potential. It is the best choice for water pump dealers to increase sales. Please partner with BISON as we work together to improve fire safety technology and community protection.

A class core parts

engine connecting rod

The mechanical strength belongs to the density of ADC12 aluminum alloy cast aluminum, and the weight monitoring can ensure the consistency of structural tensile strength and processing CPK

pump engine piston

Adopt Z109 material to increase the wear resistance and reduce thermal deformation, to ensure the weight of the piston and the accuracy of machining

pump engine case

Using high-precision fixtures, machining center equipment to ensure precision, and high-density material strength, BISON's box can meet the durability test for 125 hours, and can meet emission standards

intake and exhaust valves

BISON only adopts high-quality pump heads with sufficient materials (reasonable and thick alloy ratio) and excellent processing technology (oxidation resistance, corrosion resistance, mold, flatness, and sealing)

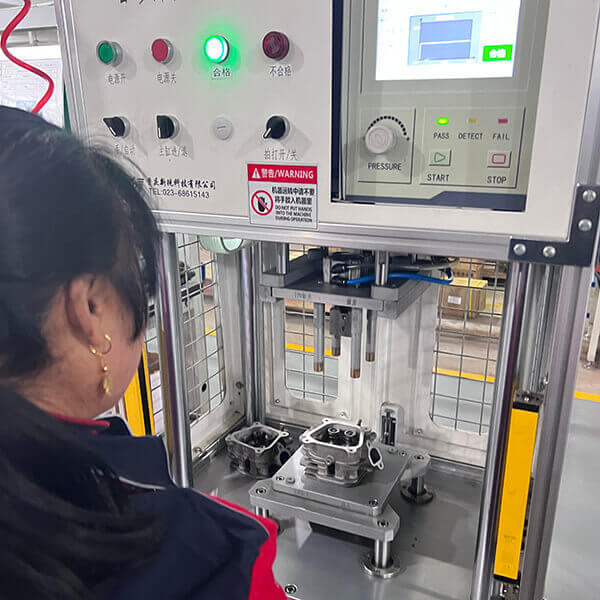

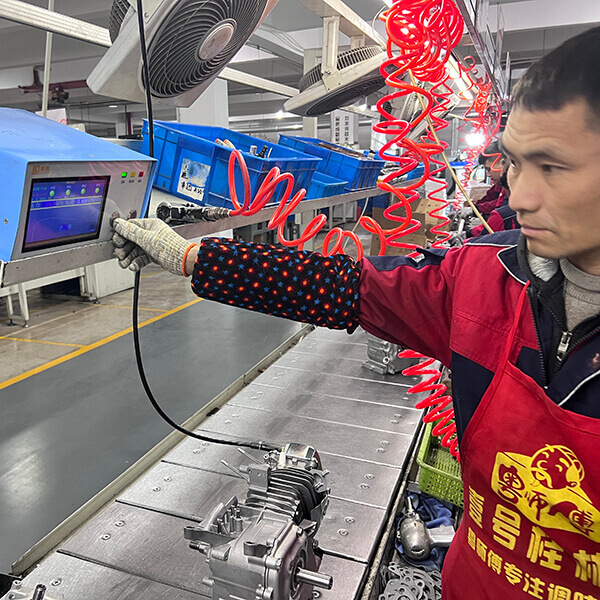

tight quality contorl

two stage fire water pump testing

BISON water pump comprehensive test bench is equipped with a comprehensive test tank, which is higher than the national standard sampling inspection type and durable, ensuring the quality of the product in all aspects.

Test the pump suction online and simulate negative pressure detection. 100% full inspection to determine the extremely low failure of the product.

Regular outdoor field testing of water pumps to ensure the pumping efficiency of the product in practice.

Professional technicians with 15-20 years of experience

Performance Commissioning

Machine Assembly

Artwork QA

Full Inspection

water pump specialized inspection

Parts assembly

Core Assembly

Power Specialized Inspection

Warranty Information

Discounted Accessories

24-hour online, 5-minute response

Engineer on-site service

Packaging & Delivery

Packaging details: brown strong carton, water pump is protected with poly bag, wooden, 1pc / carton.

Lead Time: Shipped in 25 days after payment.

Speak with a BISON sales manager

Contact us today for expert advice.

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)