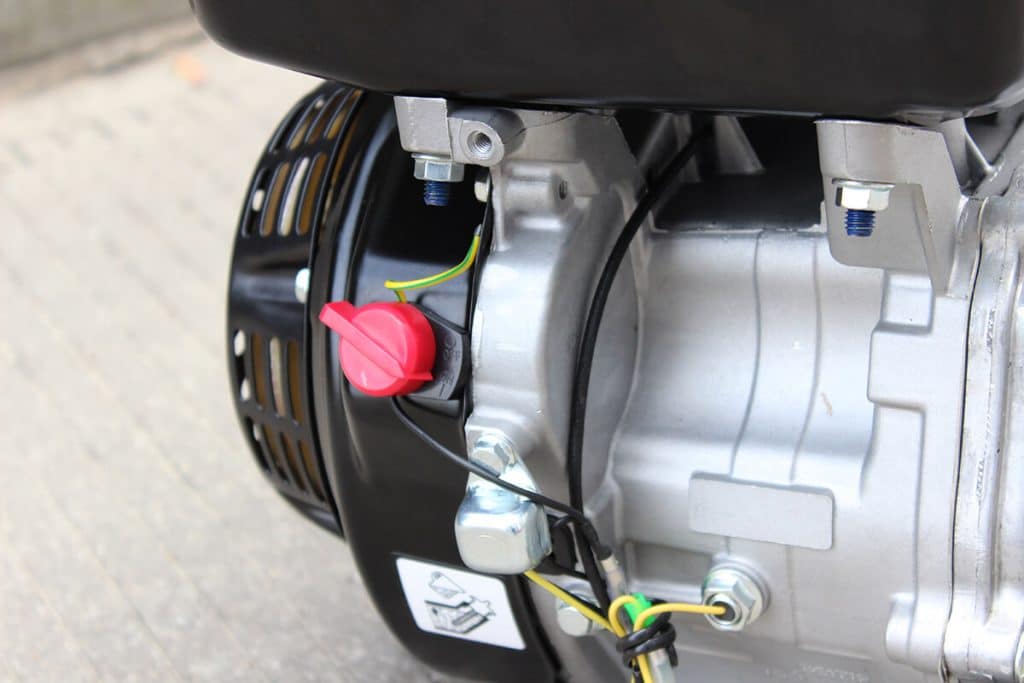

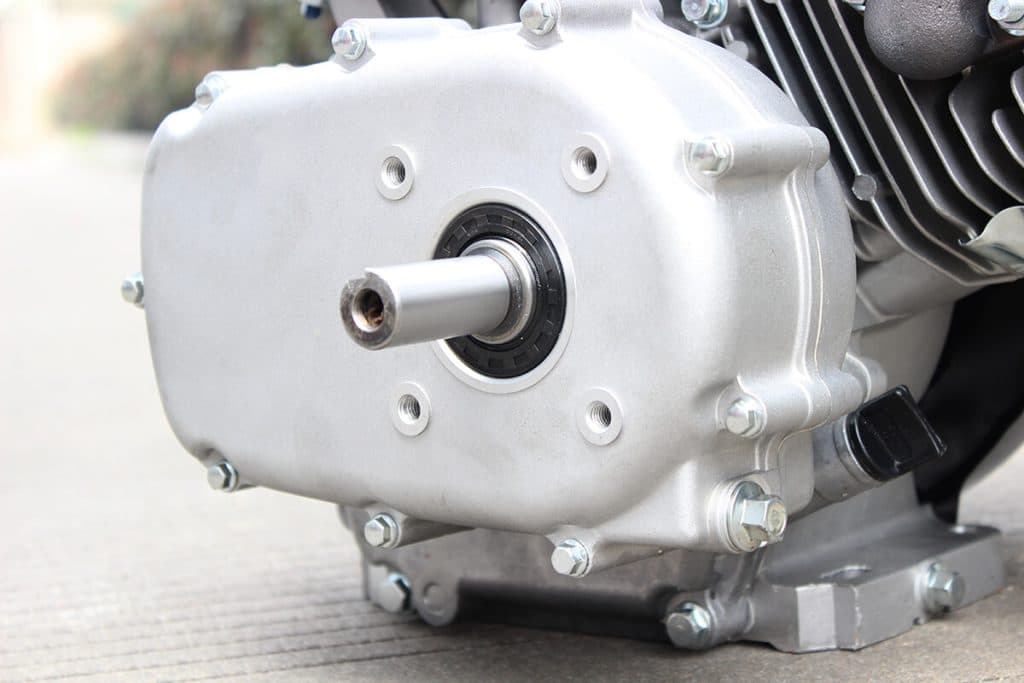

2:1 clutch reduction gasoline motor

Easy to start, easy to operate, broader applicable, scope good adaptability, logo design & colour customize. (OEM & ODM is available) Well controlled spare parts supply chain.

| no brand | 30 sets |

| OEM standard | 50 sets |

| OEM special | 100 sets |

168F-1 Specifications

| Engine & Emission Specifications | |

|---|---|

| engine model | BS168F-1 1/2 reduction motor |

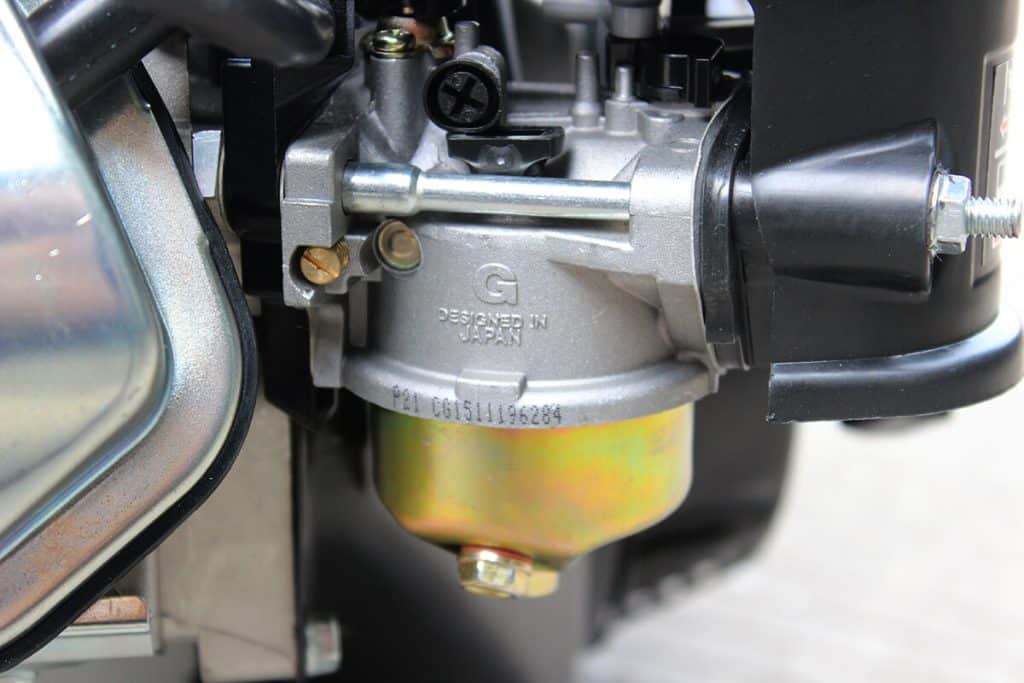

| fuel type | Gasoline |

| engine speed | 6.5hp/1800rpm;32.6N.m/1250rpm |

| Bore * Stroke | 68*54 mm |

| engine displacement | 196cc |

| power of engine (hp) | 6.5HP |

| compression ratio | 8.2:1 |

| engine type | 1-Cylinder, Air-Cooled, 4-Stroke, Direct Injected, OHV |

| engine oil grade | #5W-40 |

| fuel capacity | 3.6L |

| oil capacity | 0.6L |

| low oil shutdown/alert | Yes |

| recoil start | Yes |

| electric start | Optional |

| Fuel consumption radio | ≤395g/kW/h |

| Ignition system | T.C.I |

products description

BISON, a globally well-known professional gasoline motor manufacturing leader, launches 2:1 clutch reduction gasoline motor. This innovative motor combines the gasoline engine’s high performance and the additional advantages of a 2:1 clutch reduction gearbox, making it an ideal choice for gasoline motor dealers.

2:1 clutch reduction motor design at its core ensures optimal efficiency by reducing output shaft speed to half engine speed. Enhanced torque output reduces wear on critical components and extends motor life for long-lasting productivity.

Utilizing gasoline motor, this delivers unparalleled performance in many applications. Its powerful gasoline-powered motor ensures consistent, reliable operation even in the most demanding environments. Compared with diesel motor, it is more environmentally friendly, has a higher energy utilization rate, and ensures long-lasting working time.

2:1 clutch reduction gasoline motor applications:

- Go kart

- Wood splitter

- Industrial lawn mower

- Concrete mixer

- High pressure water pump

- High pressure washer

- And many other applications requiring high torque at low speeds

With 2:1 clutch reduction gasoline motor, you can deliver low-speed, high-torque power to your customers: from powering agricultural machinery to driving industrial equipment. BISON’s cutting-edge motor technology ensures quality, enhances your product reviews and provides you with customized support. Please contact us for more information about BISON 2:1 clutch reduction gasoline motors and prices.

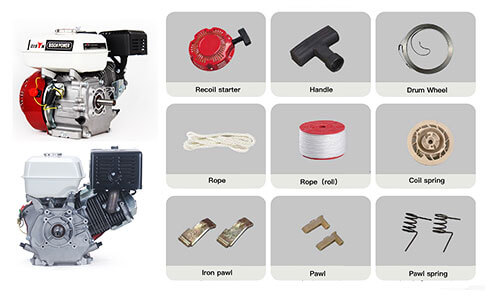

Our engine parts

Engine connecting rod

The mechanical strength belongs to the density of ADC12 aluminum alloy cast aluminum, and the weight monitoring can ensure the consistency of structural tensile strength and processing CPK

Engine piston

Adopt Z109 material to increase the wear resistance and reduce thermal deformation, to ensure the weight of the piston and the accuracy of machining

Engine case

Using high-precision fixtures, machining center equipment to ensure precision, and high-density material strength, BISON's box can meet the durability test for 125 hours, and can meet emission standards

Intake and exhaust valves

The valve is made of 40Cr10SiMo material. The exhaust valve can withstand high combustion temperature. When the load is heavy or the combustion condition is abnormal, the temperature limit will not be affected if the temperature limit is lower than 700-780°C.

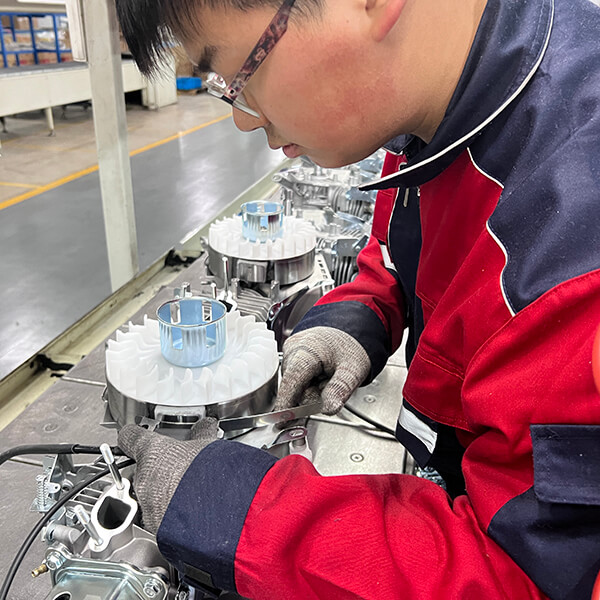

Engine testing

Dedicated to engine testing, and equipped with quality control for sampling testing. BISON verifies and confirms the performance and reliability of each batch of engines to avoid possible product failures.

Guarantee the sealing performance of the crankcase body structure and installation. Through professional instrument testing, poor sealing defects of installation and materials can be found, so as to avoid oil leakage and oil leakage of the engine and ensure the actual power efficiency.

The load output stability of the power can be confirmed online, and the configuration can be locked after stabilization to ensure high product consistency

Professional technicians with 15-20 years of experience

performance commissioning

engine assembly

artwork QA

full inspection

engine specialized inspection

parts assembly

core assembly

power specialized inspection

SupplyAbility

10000 Set/Sets per Month

Warranty Information

Discounted Accessories

24-hour online, 5-minute response

Engineer on-site service

Packaging & Delivery

Packaging Details: brown strong carton, gasoline motor is protected with ploy bag, wool, 1pc / carton, Port: Ningbo/Shanghai Port, Lead Time: Shipped in 25 days after payment

Speak with a BISON sales manager

Contact us today for expert advice.

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)