diesel generator components

BISON will explore the key components of diesel generators and understand how each part contributes to their overall performance and reliability.

Common reasons why your generator leaks gasoline

In this guide, BISON covers common causes of gasoline leaks, warning signs to watch for, and how to fix the issue.

portable or standby generators: which one fits your needs?

This article by BISON breaks down the differences between portable and standby generators. By the end, you’ll find which one fits your needs best.

open frame vs. closed frame inverter generators

This article aims to walk you through the key differences between open and closed inverter generators, helping you make an informed decision

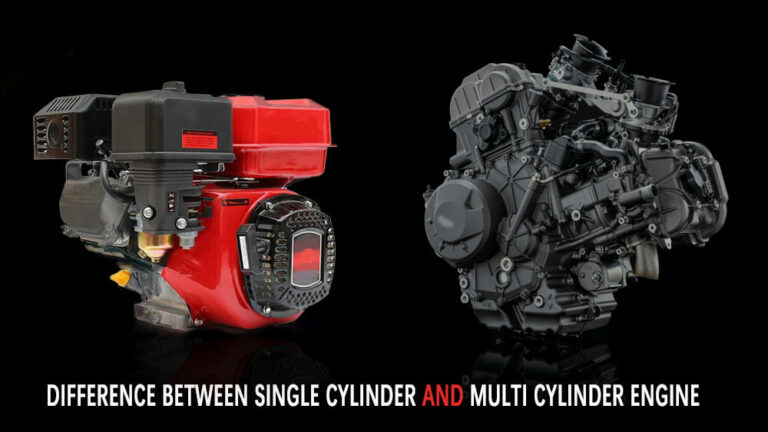

difference between single cylinder and multi cylinder engine

This article looks at single and multi cylinder engines, explains their differences, pros and cons. BISON will learn the types of machines and tasks they are suitable for.

airlocks in water pumps

BISON will walk you through the causes, signs, and troubleshooting steps of air locks to help you restore the functionality of your water pump.

water pump problems and solutions

Having trouble with your water pump? This article will guide you through practical solutions to these common issues.

difference between commercial and industrial pressure washers

This article compares the key differences between commercial and industrial pressure washers to help you choose the best option for your unique needs.

gasoline water pump vs electric water pump

BISON will discuss two main types of water pumps: gasoline and electric. We’ll compare their advantages and disadvantages…

how to properly prime a gasoline water pump

BISON this guide will show you how to safely prime your gasoline water pump step by step. Follow along to protect your water pump.

How to clean your garden patio using a pressure washer

This guide by BISON will walk you through each step to clean your garden patio with a pressure washer.

use pressure washer to clean gutters

BISON will explore whether using a pressure washer to clean your gutters is effective, safe, and practical.

how to parallel generators: A comprehensive guide

BISON will explain what parallel generators mean and how they work together as a system. We will also focus on the advantages and reliability.

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)