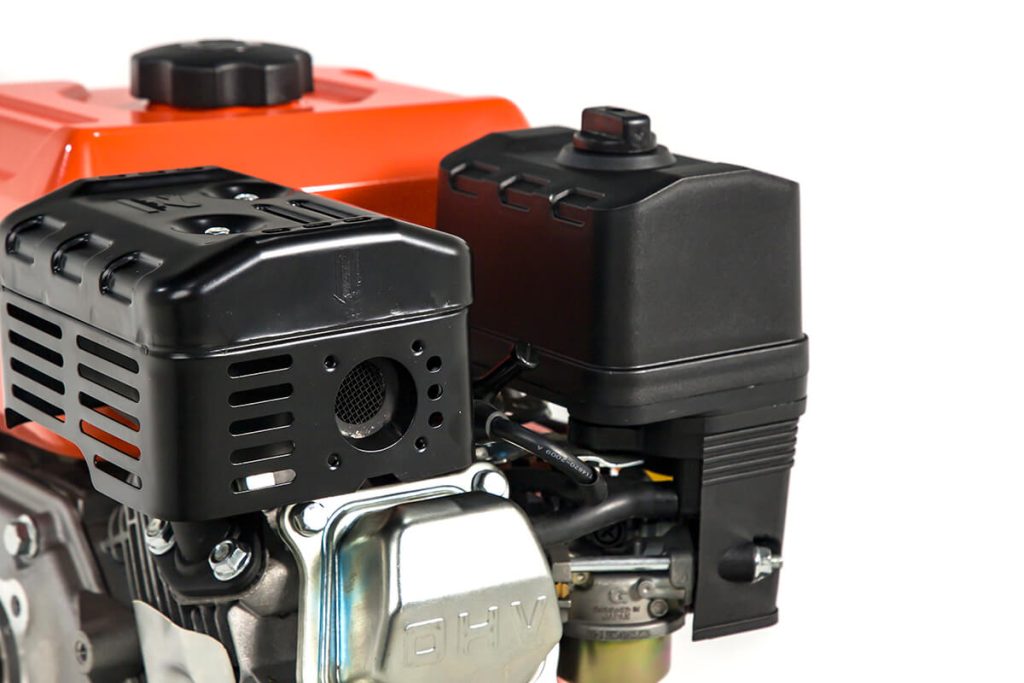

170F air cooled petrol engine

- New technology, super silent

- Long run time

- Economic, reliable, durable

- CE,ISO9001 Standard.

- High RPM

- smooth running with minimal vibration

- Light weight, low cost

| no brand | 30 sets |

| OEM standard | 50 sets |

| OEM special | 100 sets |

170F Specifications

| Engine & Emission Specifications | |

|---|---|

| engine model | BS170F |

| fuel type | Gasoline |

| engine speed | 3000/3600RPM |

| Bore * Stroke | 70*54/56 mm |

| engine displacement | 210cc |

| power of engine (hp) | 7.0HP |

| compression ratio | 8.2:1 |

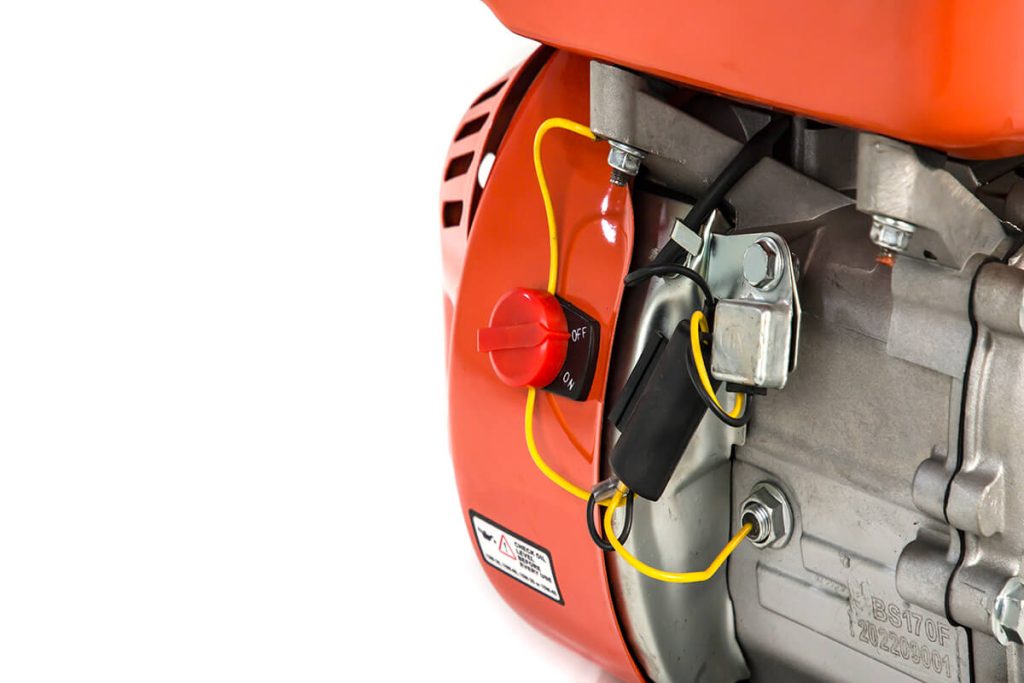

| engine type | 1-Cylinder, Air-Cooled, 4-Stroke, Direct Injected, OHV |

| engine oil grade | #5W-40 |

| fuel capacity | 3.6L |

| oil capacity | 0.6L |

| low oil shutdown/alert | Yes |

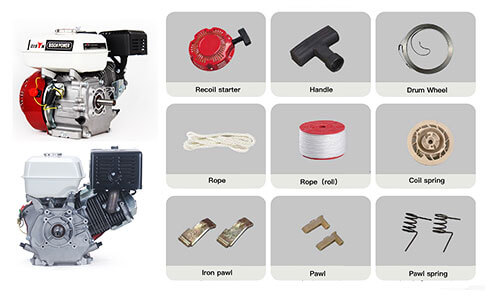

| recoil start | Yes |

| electric start | Optional |

| fuel consumption radio | ≤395g/kW/h |

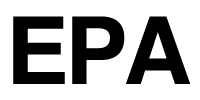

| ignition system | T.C.I |

products description

BS170F is an air cooled petrol engine. The purpose of 170F engine is to convert internal energy into kinetic energy. It uses gasoline as fuel, which is pumped through a jet system into the cylinder and then makes it inflate. It has various advantages such as high speed, simple structure, light quality, low cost, stable operation convenient maintenance, etc.

The air-cooled system is efficient. The small size and compact structure. It is portable and movable. It has low noise level and vibration, large stable power output. It is easy to pull and quick to start. Low fuel consumption makes it economical. The engine is also suitable for generator, water pump, compressor, mini-tiller, high pressure washer

The following points are noted while using 170F air cooled petrol engine:

- During the off-job period after the engine overhaul, strict operation rules and regulations on load reduction and deceleration should be implemented;

- Keep the correct ignition timing to avoid setting the ignition timing too early and causing the engine to burst and overheat;

- Ensure sufficient oil that meets the original factory specifications. Check the oil pressure frequently, and change the oil according to the requirements of the departure period;

- Add enough cooling water and always check the cooling water and water temperature.

BISON 170F air cooled petrol engine provides engine dealers with several advantages:

- Supply capacity: with the ability to produce 10,000 sets per month, dealers don’t have to worry about inventory shortages and shipment delays.

- Certification: BISON engines have certificates such as CE and ISO, ensuring that the generator meets necessary safety, health and environmental standards, increasing the credibility for dealers and customers.

- Warranty: BISON offers one-year warranty and any issues your customers may have during the warranty period will be resolved, thereby increasing trust in your brand.

- Customization options: BISON offers customization options such as recoil start, electric start and color changes. This flexibility allows dealers to meet a wider range of customer needs, thereby expanding market reach and increasing sales potential.

- By leveraging these strengths, engine dealers can strengthen their market competitiveness, attract more customers.If you want to get more information about 170F air cooled petrol engine, you can contact us directly!

Our engine parts

Engine connecting rod

The mechanical strength belongs to the density of ADC12 aluminum alloy cast aluminum, and the weight monitoring can ensure the consistency of structural tensile strength and processing CPK

Engine piston

Adopt Z109 material to increase the wear resistance and reduce thermal deformation, to ensure the weight of the piston and the accuracy of machining

Engine case

Using high-precision fixtures, machining center equipment to ensure precision, and high-density material strength, BISON's box can meet the durability test for 125 hours, and can meet emission standards

Intake and exhaust valves

The valve is made of 40Cr10SiMo material. The exhaust valve can withstand high combustion temperature. When the load is heavy or the combustion condition is abnormal, the temperature limit will not be affected if the temperature limit is lower than 700-780°C.

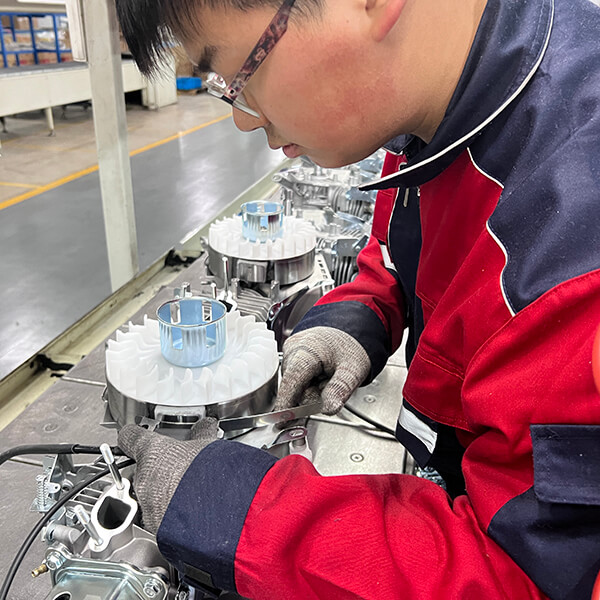

Engine testing

Dedicated to engine testing, and equipped with quality control for sampling testing. BISON verifies and confirms the performance and reliability of each batch of engines to avoid possible product failures.

Guarantee the sealing performance of the crankcase body structure and installation. Through professional instrument testing, poor sealing defects of installation and materials can be found, so as to avoid oil leakage and oil leakage of the engine and ensure the actual power efficiency.

The load output stability of the power can be confirmed online, and the configuration can be locked after stabilization to ensure high product consistency

Professional technicians with 15-20 years of experience

performance commissioning

engine assembly

artwork QA

full inspection

engine specialized inspection

parts assembly

core assembly

power specialized inspection

QC System

During the production, BISON care about the quality for each 170F air cooled petrol engine, that’s why we strictly follow the step of our QC system. Every product will be well test during the production line, we separate the faulty one to special area-faulty zone, where the place will collect faulty product and send to repair.

ERP system

With full using of ERP system, once we receive your order, all steps proceed methodically, it improves our work efficiency and reduces our error rate。And it give our loyal customers more confidence.

Production system

From the beginning of the product production, BISON skilled operate equipment to manufacture high level quality 170F air cooled petrol engine. All steps by our own workers.

Warranty Information

The staff of the maintenance service department must continuously learn, improve and improve their own technical level, provide services for customers, and strictly follow the relevant company system and code of conduct to ensure that they are “friendly, enthusiastic and responsive”We will offer the technical support through phone call,internet if customer require.

If transportation,installation, faulty operation problem,lead to the equipment’s part damage.That will not have a warranty, but we will present the part to customer in a low price.

Discounted Accessories

24-hour online, 5-minute response

Engineer on-site service

Packaging & Delivery

Packaging details: brown strong carton, engine is protected with poly bag, wooden, 1pc / carton. Lead Time: Shipped in 25 days after payment.

Speak with a BISON sales manager

Contact us today for expert advice.

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)