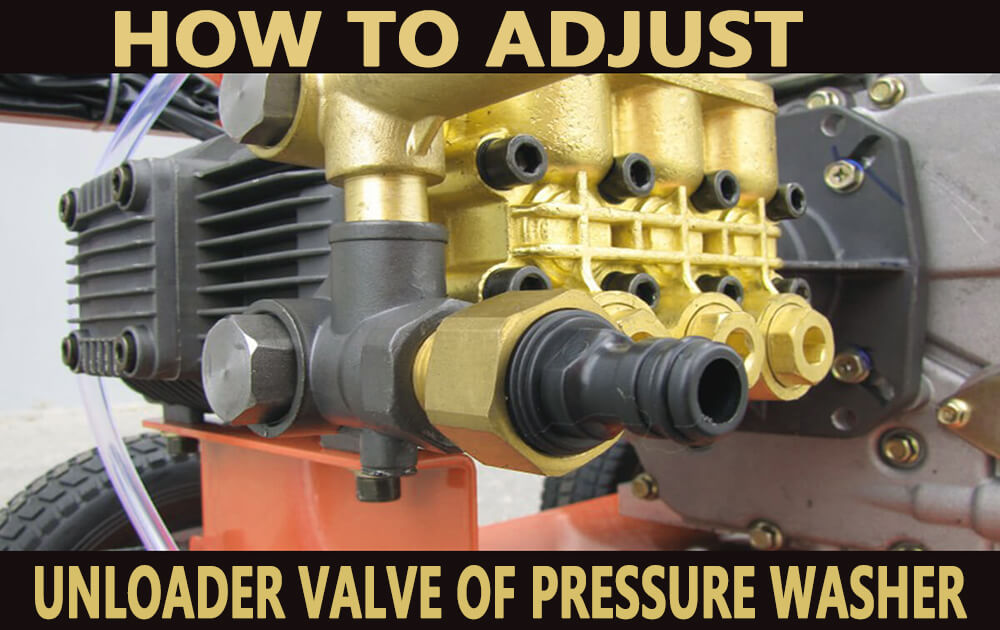

how to set the unloader valve of pressure washer

- By BISON

Table of Contents

Unloader valve is a vital component of pressure washer, controlling water flow and pressure. When you let go of the trigger, it reroutes water back to the pump to avoid excess pressure. This safeguards both the safe use of pressure washer and the longevity of pump.

It’s crucial for any pressure washer owner to grasp the significance of unloader valve. When it works well, it guarantees peak cleaning efficacy and extends your machine’s lifespan. On the other hand, an incorrect setting can result in uneven pressure, reduced performance, and possibly even failure of the pressure washer.

This blog is designed to guide you through the process of setting unloader valve on pressure washer. BISON will provide a step-by-step approach. So, whether you’re seasoned professional or weekend DIYer, join us in realizing the full potential of your pressure washer!

How unloader valve works?

The unloader valve is crucial for pressure washer’s function. When you pull the trigger, it lets water flow at high pressure for effective cleaning. Releasing the trigger activates the unloader valve, which then redirects water back to the pump. This prevents pressure buildup and protects pump from overheating, ensuring the machine can restart smoothly later. Unloader valve automatically adjusts based on the system’s pressure, ensuring pressure washer safe and efficient operation.

Signs of a malfunctioning unloader valve

Identifying signs of faulty unloader valve is key to keeping pressure washer running smoothly. Common indicators include:

- Unstable pressure: If you experience inconsistent water pressure during use, it may indicate a malfunction in the unloader valve.

- Continuous water flow: A faulty or jammed unloader valve can lead to water flow even when trigger is not pressed.

- Excessive noise: Loud, strange noises from pump could signal issues with unloader valve, like wear or misalignment.

- Leaking water: If the unloader valve leaks water, it might require adjustment or replacement.

Understanding how the unloader valves work, their various types and signs of failure helps keep your pressure washer running smoothly. In the following sections, BISON will thoroughly explain how to correctly set unloader valve and improve the performance of your pressure washer.

Setting the pressure unloader valve on pressure washer

setup preparation

Before making any settings to the pressure unloader valve, it is important to fully prepare to ensure safety and effectiveness:

First, shut off the pressure washer completely. Disconnect the power supply to prevent accidental startup during the setting process.

Now, discharge the built-up pressure from the pump. Squeeze the trigger, aiming the gun safely away from yourself. This prevents injuries and equipment damage.

Check the pressure unloader valve for any visible damage, wear, or obstructions. Keeping it clean and operational can help to achieve precise settings.

steps to setting the pressure unloader valve

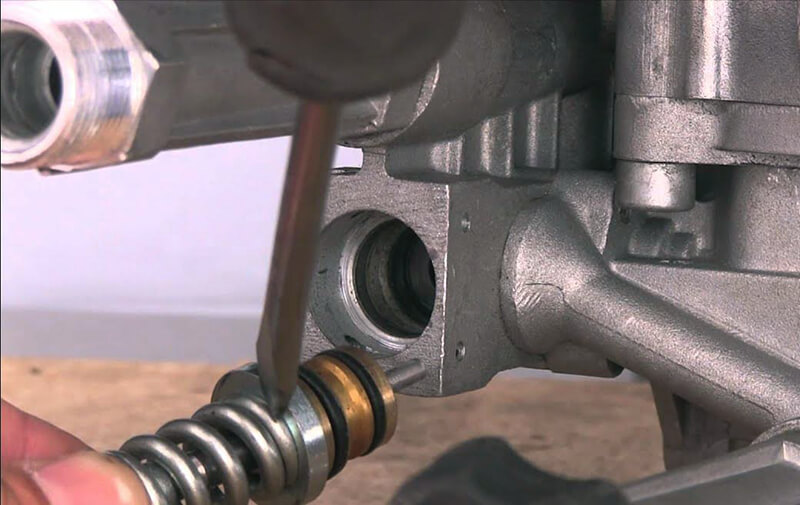

With the prep work complete, you can now make settings:

Find the unloader or pressure unloader valve, typically near the pump outlet or hydraulic line. Check your pressure washer’s manual if needed, since valve locations can differ by model.

Next, adjust the pressure setting: This may need a wrench or screwdriver, based on the type of valve.

- How to increase pressure? To increase pressure, rotate the adjustment knob or screw to the right. Make small adjustments and check the pressure gauge frequently to prevent going too far.

- How to decrease pressure? Conversely, to decrease pressure, rotate the adjustment knob or screw counterclockwise. Make small adjustments and verify the pressure gauge after each change.

Check for leaks and proper function after set: Inspect the fittings visually for any leakage. Confirm valve seals tightly and there’s no water escaping.

Post-setup test

After making the settings, test the pressure washer to confirm it’s working correctly. Reconnect the power supply and start the pressure washer. Let it run for a few moments to reach operating pressure. Use the pressure washer on the ground to evaluate its performance. Note the pressure consistency and how the pressure flows when the trigger is engaged and released.

If you notice anything unusual, such as inconsistent pressure or leaks, go back to the setting process. Fine-tune the pressure unloader valve setting as needed, repeating the testing phase until optimal performance is achieved.

By adhering to these steps, you ensure your pressure washer performs optimally, delivering top cleaning outcomes for your requirements.

Common troubleshooting for pressure washer unloader valves

When you tweak the unloader valve on a pressure washer, pressure levels can be inconsistent. Here are some typical steps to troubleshoot:

If the setting doesn’t normalize the pressure, the issue extends beyond the unloader valve settings. This might suggest a faulty pump or a blockage, necessitating further examination.

If the set fails to yield the desired outcomes, explore other potential reasons. Inspect worn seals, damaged hoses, or blockages in the system. These factors can affect performance and may require immediate attention.

If troubleshooting doesn’t fix the problem, check your pressure washer’s manual for detailed advice on symptoms and fixes. And should the issue continue, you can seek help from a professional technician for accurate diagnosis and repair.

Unloader valve maintenance tips

Maintaining unloader valve in good shape is important for your pressure washer’s health and performance. Here are some maintenance tips:

Get into regularly inspecting and cleaning your unloader valve. Look out for any debris, dirt or buildup that might hinder its function. A clean valve ensures proper flow and reduces the chance of failure.

Watch for signs that you need professional help. These signs include persistent leaks, unusual noises, or a significant drop in pressure despite steeings. These issues often indicate an underlying problem that requires expert evaluation.

When replacing any part, including the unloader valve, always use quality parts. Low-quality or incompatible parts can lead to failure and additional repair costs. Investing in quality ensures better performance and durability from your pressure washer.

By these troubleshooting and maintenance tips to enhance your pressure washer’s longevity and performance. Regularly checking your unloader valve ensures consistent outcomes, keeping your machine ready for any cleaning task.

Conclusion

In this article, we discussed how unloader valves work, signs of failure, and the step-by-step process for setting a pressure unloader valve. Additionally, BISON covers troubleshooting tips for ongoing issues and provides maintenance recommendations to keep your equipment running smoothly.

A proper set is essential to achieving optimal performance and ensuring the life of your pressure washer. A properly set unloader valve not only improves cleaning efficiency but also prevents potential damage to your machine.

With this knowledge in hand, BISON encourages you to act now! Examine your pressure washer’s unloader valve closely and set as needed. Don’t wait. Unleash the full potential of your equipment and enjoy better, more efficient cleaning results today!

Most Popular Posts

QUESTIONS?

CONTACT US TODAY.

buy?

Related Posts

difference between commercial and industrial pressure washers

This article compares the key differences between commercial and industrial pressure washers to help you choose the best option for your unique needs.

How to clean your garden patio using a pressure washer

This guide by BISON will walk you through each step to clean your garden patio with a pressure washer.

use pressure washer to clean gutters

BISON will explore whether using a pressure washer to clean your gutters is effective, safe, and practical.

pressure washer won’t start: troubleshooting and DIY fixes

Your pressure washer motor may not start for various reasons. In this comprehensive guide, BISON will lead you through the most common culprits of pressure washer rebellion.

Related Products

gasoline engine power high pressure washer

As one of the most professional gasoline engine power high pressure washer suppliers in China,

best pressure washer with factory price

Flushing flow rate is 9L per minute. This pressure washer only needs water to achieve

car power washer for cleaning & detailing

As one of the most professional car power washer for cleaning & detailing suppliers in

frequency conversion pressure washer

The E550 frequency conversion pressure washer manufactured by BISON adjusts pressure for versatile, safe cleaning,

.png)

-qbpqbzxxvtguiuwezisu6wo6j1i29b4m1el1ir1u8o.png)